Flowmeters are the key to measuring fluid flow in piping systems or open channels. Although all types of flowmeters allow you to control flow, there are some significant differences between electromagnetic and ultrasonic flowmeters.

The differences between electromagnetic and ultrasonic flowmeters include the work principle, types of fluids that can be measured, installation method, advantages, and application examples.

This article will explore the key differences between electromagnetic and ultrasonic flowmeters to control flow in several industries.

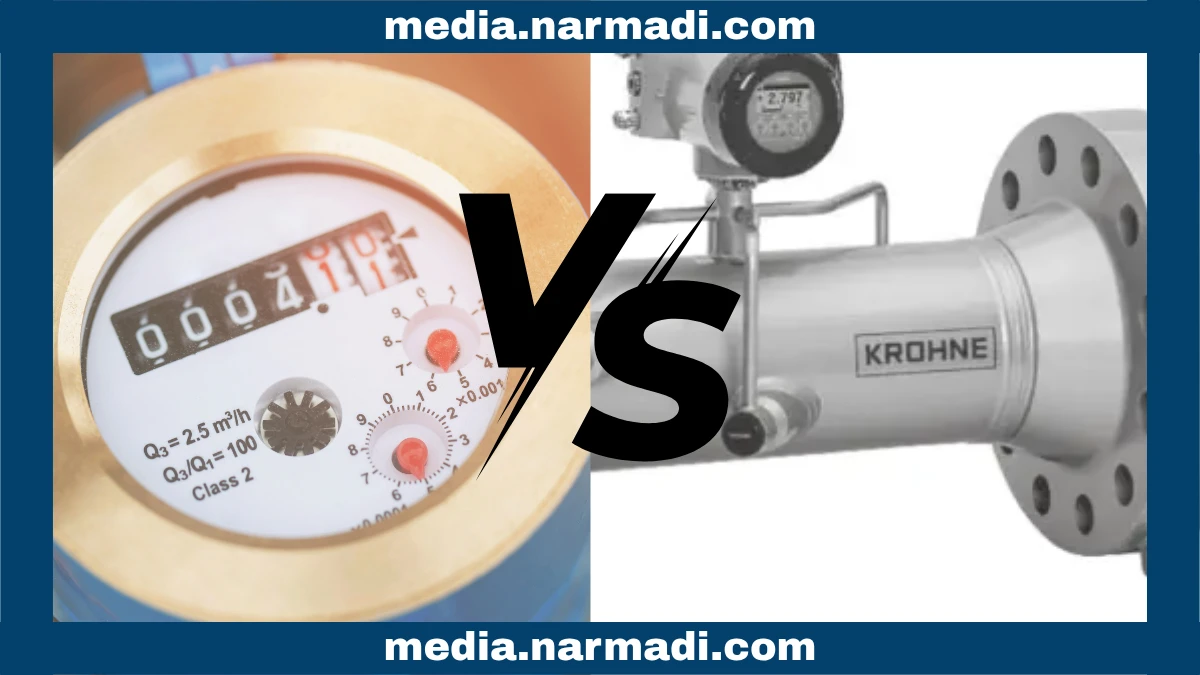

What is an Electromagnetic Flowmeter?

An electromagnetic flowmeter is a type of device used to measure the flow rate of conductive liquids such as water, liquid waste, and chemical solutions. These devices use the principle of electromagnetic induction to determine the speed of flowing liquids. The readings of these devices are not affected by pressure, temperature, or viscosity, resulting in accurate data.

Various industries, such as water treatment, manufacturing, energy, and food processing, use these devices because of their high-precision measurement capabilities and minimal maintenance requirements. Some modern models are equipped with Bluetooth connectivity so they can be operated remotely via a smartphone or computer.

What is an Ultrasonic Flowmeter?

An ultrasonic flowmeter is a type of flowmeter that determines flow velocity using ultrasonic waves. Flow velocity is measured by the time difference between the sound waves emitted from one sensor to another sensor installed on the pipe.

This type of flowmeter has the advantage of installation flexibility, as it is placed outside the pipe without having to cut the flow path, thus not causing fluid flow resistance. Sectors that use ultrasonic flowmeters are usually the oil, chemical, and energy industries.

The Differences of Electromagnetic and Ultrasonic Flowmeters

Electromagnetic and ultrasonic flowmeters are devices that allow you to have good safety. Here are the differences between them:

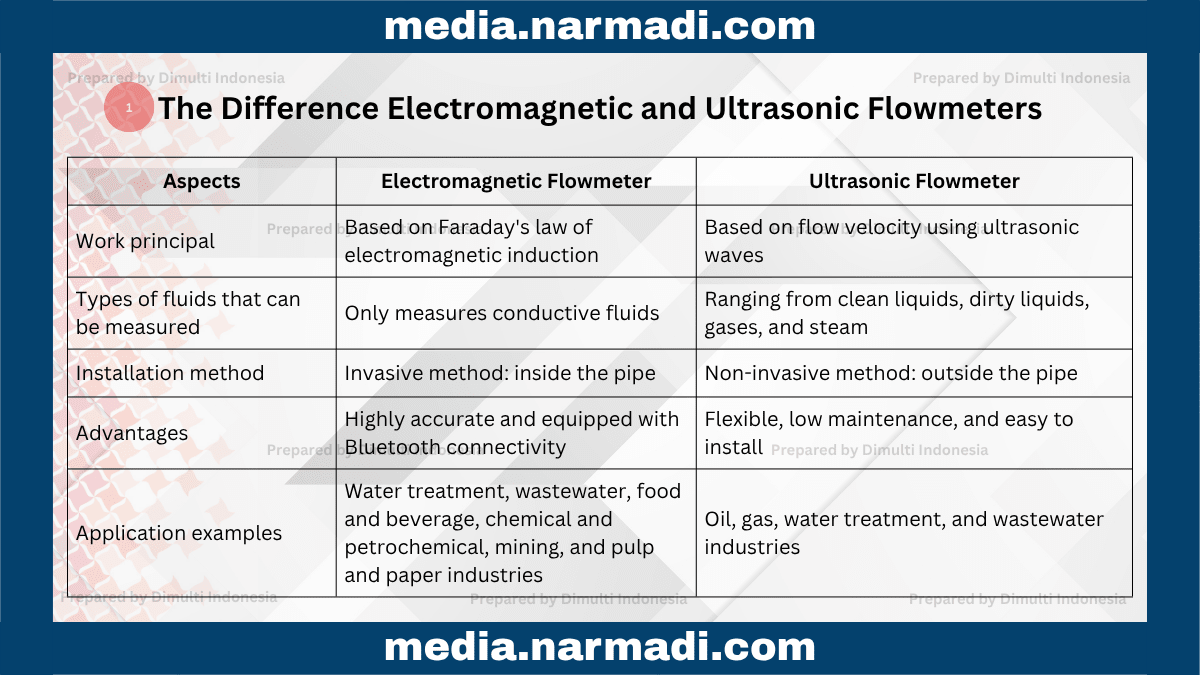

Work principle

Electromagnetic flowmeter: Operates based on Faraday's law of electromagnetic induction, which measures the voltage induced when a conductive fluid cuts through a magnetic field.

Ultrasonic flow meter: Operates based on flow velocity using ultrasonic waves, which measure the time difference between sound waves between two transducers attached to the pipe.

Types of fluids that can be measured

Electromagnetic flowmeter: Only measures conductive fluids, such as water, wastewater, and most chemicals.

Ultrasonic flowmeter: Can measure various types of fluids, ranging from clean liquids, dirty liquids, gases, and steam.

Installation method

Electromagnetic flowmeter: Uses an invasive method that requires installation inside the pipe. Ultrasonic flowmeter: Uses a non-invasive method that is installed outside the pipe.

Advantages

Electromagnetic flowmeter: Highly accurate and equipped with Bluetooth connectivity for remote control. Ultrasonic flowmeter: Flexible, low maintenance, and easy to install.

Application examples

Electromagnetic flowmeter: Used in water treatment, wastewater, food and beverage, chemical and petrochemical, mining, and pulp and paper industries.

Ultrasonic flowmeter: Used in oil, gas, water treatment, and wastewater industries.

That’s the difference between electromagnetic and ultrasonic flowmeters that you can consider when choosing according to your personal needs.

If you want a liquid meter with high accuracy and Bluetooth connectivity for remote control, an electromagnetic flowmeter is a good choice. However, if you want a flexible meter that requires minimal maintenance and is easy to install, you can choose an ultrasonic flowmeter.