Many industrial operations require accurate flow measurements, ranging from water treatment plants to chemical manufacturing and energy distribution. Therefore, electromagnetic flowmeters are needed as precise and efficient measuring devices.

Electromagnetic flowmeters use the principle of electromagnetic induction to measure the velocity of conductive liquids. This makes their readings stable and accurate even under changing pressure or temperature conditions.

Are you still unfamiliar with this device? Don't worry, this article will provide more detailed information about electromagnetic flowmeters, including their definition, how they work, their types, and how to use them.

What is an Electromagnetic Flowmeter?

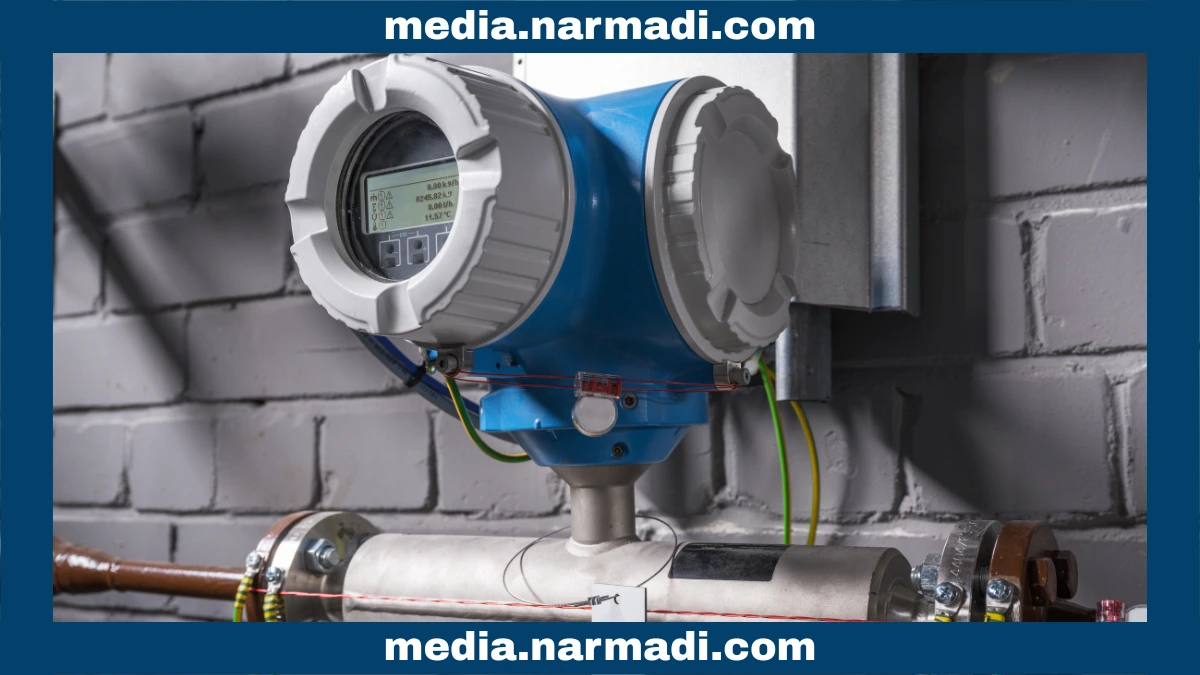

Electromagnetic flow meters are devices used to measure the flow rate of conductive liquids such as water, wastewater, and chemical solutions. These devices use the principle of electromagnetic induction to determine the velocity of the flowing liquid. The readings of these devices are not affected by pressure, temperature, or viscosity, resulting in accurate data.

Electromagnetic flowmeters have become essential devices in various industries, such as water treatment, manufacturing, energy, and food processing. Various industries use this device because it is capable of high-precision measurement and requires minimal maintenance.

Currently, modern flowmeters are integrated with IoT-based monitoring systems. These modern systems enable real-time data tracking, smarter industrial operations, and efficient work.

How Does an Electromagnetic Flowmeter Work?

Electromagnetic flowmeters work based on Faraday's law of electromagnetic induction. This law states that the induced electromotive force generated in a closed circuit is directly proportional to the rate of change of the magnetic flux surrounding it.

In order to function, electromagnetic flowmeters rely on interconnected components, namely measuring pipes, electromagnetic coils, electrodes, and transmitters. The measuring pipe serves as a channel through which conductive liquids flow, while the electromagnetic coil generates a magnetic field around the pipe.

The electrical voltage captured by the electrodes induces a current in the fluid. The electrical signal is then processed by the transmitter to produce flow data that can be displayed.

The following is the sequence of operations:

- Conductive fluid passes through the measuring pipe.

- The electromagnetic coil generates a magnetic field.

- The interaction between the fluid flow and the magnetic field induces an electrical potential difference.

- The voltage formed is captured by the electrodes.

- The electrodes transmit the flow to the transmitter.

- The transmitter converts the electrical signal into quantitative information, such as flow velocity, discharge, or fluid volume.

With this method, the measurement results remain accurate and are not affected by temperature, pressure, or fluid viscosity.

The Types of Electromagnetic Flowmeters

Based on their installation, electromagnetic flowmeters are divided into three types, namely the inline type, the insertion type, and the portable type. Here is the explanation:

Inline type

An inline type is a type of electromagnetic flowmeter that is installed directly in the pipeline. The magnetic field in this type of flowmeter is an important part because it affects the entire water cross-section. As a result, measurements are more accurate, corrosion-resistant, and require minimal maintenance. This type is suitable for small to medium-sized pipes.

Insertion type

The insertion type is a type of electromagnetic flowmeter that is installed by inserting it into a pipe that has been drilled. Its advantages are easy installation, flexible installation, and more economical. This type is suitable for large diameter pipes.

Portable type

The portable type is an electromagnetic flowmeter that can be carried around. This type generally does not require pipe cutting during installation. Its advantages are portability, no damage to the pipe, and versatility. This type is suitable for field measurements.

Electromagnetic Flowmeter Regulation

An electromagnetic flowmeter utilizes Bluetooth technology, which operates within a specific frequency spectrum. In every country, all Bluetooth-based wireless devices are required to have Radio Frequency (RF) Certification.

Electromagnetic flowmeter regulations require all radio frequency-based devices to meet certain technical standards before they can be sold in that country. This certification ensures that the product complies with government safety and quality regulations and does not interfere with other communication devices.

The certification process involves technical testing, such as frequency adjustment, safety checks, and compatibility with the surrounding environment. Once testing is complete, products that pass will be listed in a Test Report, confirming that they are safe and ready for sale. This report assures customers that the product meets technical standards and is safe.

For companies wishing to sell electromagnetic flowmeters, Product Compliance Specialists are available to assist with this process. This service includes preparing technical and legal documents, conducting the necessary testing, ensuring regulatory compliance, helping companies streamline the certification process, and providing consumers with confidence in certified products.