In the food, pharmaceutical, and other consumer goods industries, there is an essential tool. It is the inkjet printer for expired dates. This printer is not just a tool for printing expiration dates, but a tracking requirement driven by global standards, safety regulations, and consumer expectations.

The technology behind the inkjet printer expired date plays a crucial role in ensuring that products have accurate, durable, and compliant date codes. This technology also promotes production efficiency optimization and maintains brand integrity in a competitive market.

This article will discuss inkjet printer expired date, including their definition, how they work, the technology behind them, and their integration with manufacturing production lines. Additionally, we will provide a brief review of the regulations governing their use of wireless technology.

What is an Inkjet Printer Expired Date?

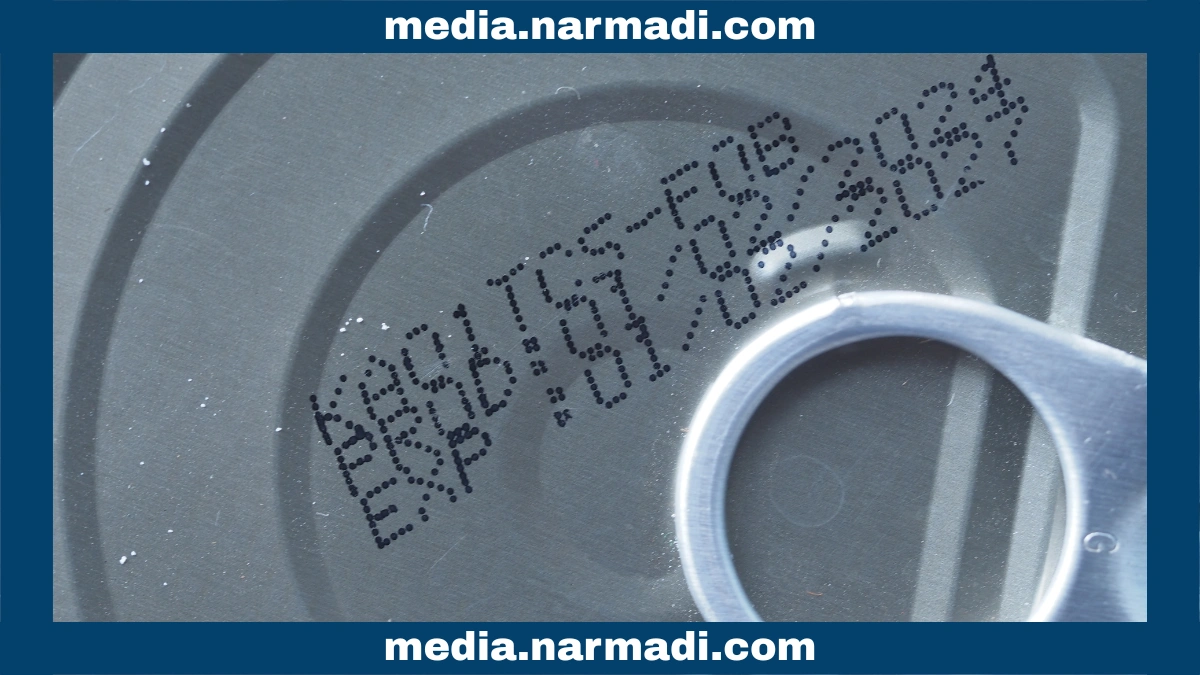

Inkjet printers are electronic devices used in the industrial sector. They are used to automatically print expiration dates, production codes, and product serial numbers.

The process is fast, precise, and produces clear writing. It can even be used on various types of materials, including plastic, paper, metal, and glass.

This flexible and efficient device is often applied in the production lines of the food, pharmaceutical, and other consumer goods industries. The aim is to ensure that each product has an accurate identity that is easily readable by consumers and tracking systems.

How Do They Work?

Inkjet printers work by simply spraying ink onto the surface of the packaging. They do not even need to touch the material directly. This makes them very effective.

This device is widely used in large-scale industries due to its ability to print continuously without interruption. Here's how it works:

- The controller prepares the variable data: The information to be printed, such as the expiration date, is set through the control system.

- Sensors detect the presence of products: Optical sensors signal when a package approaches the printing area.

- Ink is sprayed through the nozzle: The printhead sprays micro-sized ink droplets onto the surface of the packaging.

- The ink dries instantly: Within seconds, the special fast-drying solvent-based ink adheres and dries immediately.

Core Technologies That Are Used

The main technologies used for inkjet printers are Continuous Inkjet (CIJ) and Thermal Inkjet (TIJ). Both have their own working methods, advantages, and disadvantages. Here are the differences:

Continuous Inkjet (CIJ)

Continuous Inkjet (CIJ) works by continuously spraying ink through a small nozzle to create text. Its advantage is that it is suitable for very high production and can print on various surfaces.

However, it has disadvantages in terms of low print resolution and requires regular maintenance for calibration.

Application examples: Printing dates on soy sauce bottle packaging, beverage cans, snack food cartons, medicine blister packs, pipes, or chemical gallons.

Thermal Inkjet (TIJ)

Thermal Inkjet (TIJ) works by using heat to trigger a vapor bubble that pushes the ink out of the cartridge nozzle. Its advantages are that it produces high-resolution prints, requires minimal maintenance, and the ink dries quickly.

However, it has disadvantages in terms of higher operating costs and is only suitable for certain surfaces, for example, cardboard, labels, and secondary packaging.

Application examples: Printing expiration dates and batch numbers on medicine blister packs, secondary food cartons with QR codes, or cosmetic packaging boxes.

Integration in Manufacturing Production Lines

Integrating inkjet printers for printing expiration dates into manufacturing production lines involves using Continuous Inkjet (CIJ) and Thermal Inkjet (TIJ) systems. They are designed for high-speed production environments.

These machines excel at synchronized variable data printing (VDP), including expiration dates, manufacturing dates, batch or lot numbers, and QR codes to enhance traceability. Each product receives a unique code in real time without stopping the production line.

Regulatory Requirements

Since some products are now equipped with RFID (Radio Frequency Identification) features, these devices fall into the category of telecommunications equipment that must meet technical standards in each country. In every country, all WiFi-based wireless devices are required to have Radio Frequency (RF) Certification.

Electronic shelf label regulations require all radio frequency-based devices to meet certain technical standards before they can be sold in that country. This certification ensures that products comply with government safety and quality regulations and do not interfere with other communication devices.

Some types of type certification regulations in Asia:

- Indonesia: DJID Certification

- Malaysia: SIRIM Certification

- Thailand: NBTC Certification

- Singapore: IMDA Certification

- Philippines: NTC Certification

- Vietnam: MoST Certification

- Cambodia: TRC Certification

- India: WPC ETA and TEC MTCTE Certification

The certification process involves technical testing, including frequency adjustment, safety checks, and verification of compatibility with the surrounding environment. Once testing is complete, products that pass will be listed in a test report, confirming that they are safe and ready for sale. This report guarantees customers that the product meets technical standards and is secure.

For companies wishing to sell electronic shelf labels, Product Compliance Specialists are available to assist with this process. This service includes preparing technical and legal documents, conducting the necessary testing, ensuring regulatory compliance, helping companies streamline the certification process, and providing consumers with confidence in certified products.